Project Description

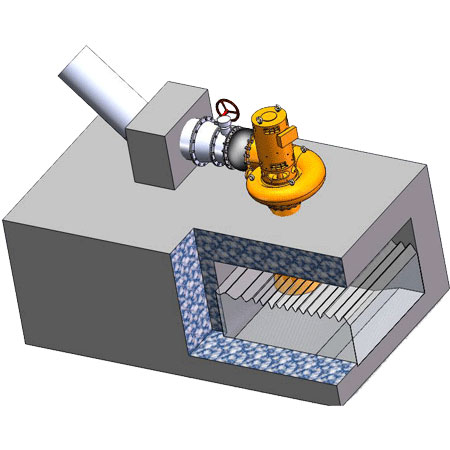

There are two types of Axial flow turbine: fixed blade Propeller turbine and adjustable blade Kaplan turbine. The blades of the fixed blade propeller turbine are fixed, but the structure is simple. When the water flow and output changes, the efficiency of it also changes and the average operation efficiency is lower, therefore fixed blade propeller turbine could be at the power station which the power is not big and the water flow does not change much, currently it is used for the hydraulic head range of 3-20 m head.

Propeller turbine Features:

- Compact structure, easy to install.

- Reliable operation, easy to control.

- Efficiency from 80%-91%, good output when flow is stable.

- it can be used at low head and stable big water flow water turbine project.

12kw-160kw Propeller turbine specification

Because different hydro power project head and flow should choose different turbine and different size turbine runner to meet, Turbine specification table can not show all the detail to meet all kind of condition of customer’s project situation, here table only for reference, so please give me your Head and Flow, together with your requirement, we will make the suitable design to meet your need, thanks.

Brushless Excitation Hydraulic Generator

- Base Seat No.: 423 – 3250;

- Single hydroelectric generator capacity: 5 KW -10,000 KW;

- Efficiency: 89-95%

- Pole number: 4 – 60

- Rotational speed: 250~1500rpm

- Voltage includes two levels: single phase 110v-120v and 220v-240v, three phase 380v-480v and 6300v.

- Insulation level: B and F

5kw-200kw micro hydropower Permanent magnet generator

- Motor casing protection grade: IP44-IP54

- Cooling method: ICO141

- Rotation speed: 125 rpm – 3000 rpm

- Efficiency: 90%-96%

- No Excitation unit needed

- Bearing: SKF

Using condition:

- Ambient air temperature: respond to the season change, but not higher than 40℃

- Elevation: less than 1000m

- Voltage: as contract requirement. The voltage is effected when the speed change.

- Current: it is related to the motor load and voltage.

- Connection method: motor principal windings Y connection, separately it is U(A)、V(B)、W(C)

- Operating procedure: S1 (continuous)

- Stator winding limited exotherm(electric-resistivity method):less than 80K.

Check left side table, you will know how much power you can get based on different Head and Flow data, if you can not find it in the table, just tell me your project Head and Flow directly.

Check below Off-grid power and Grid power selection to know what your usage for your power plant.

Check below hydropower generator selection to know what kind of generator you need for your power plant.

You still can not sure about hydropower? Click here to know more

It’s time to Build your personal home hydro turbine plant. Quote us now!

Off-grid voltage controller for micro hydro

This kind of off-grid control panel is very suitable for micro hydropower project in the Mountain area without electricity Grid, Mining areas, Vacation Villa, Temples, Farm, Community and all far away Location with water resources without electricity Grid, with competitive price and easy installation, we can offer you this kind of off-grid hydropower voltage control panel and dump load system from 300w to 300kw.

Grid inverter for microhydro

- Main circuit is using U.S. TI’ DSP chip, Infineon IGBT modules,Infineon‘s driver protection, grid-connected output part adopts isolation transformer, safe and reliable ;

- Using SPWM pulse width modulation,pure sine wave output,automatically synchronized with the grid tracking,power factor close to 1.Low current harmonic content , pollution-free and non-shock to grid;

- Hydro input maximum power tracking technique (MPPT);

- grid-connected inverter’s current closed loop control, control and regulate;

- DC voltage across a wide range of input,adapt to different circumstances demand;

- Frequency disturbance the technical, to achieve control of anti-island;

- A comprehensive power to protect and improve yourself and protect the function.In case of system failure to stop the grid-connected invert ion ;

- Circuit frame compact, ax. Efficiency≥94%;

- Protection class up to IP20 ;

- Optional RS485 communication, Upper machine monitoring, achieve the remote data collection and monitoring ;

Grid control panel for hydropower

- With main generator synch and protection circuit breaker.

- With terminals to connect to the alternator power.

- With terminals to connect to the governor.

- With suitable protection to protect against incoming mains faults.

- Generator protection functions (over current, over load, over voltage, low voltage, over-speed, low frequency and so on).

- With suitable control functions to control the alternator excitation

- With 4/20mA level input and control function to allow load adjustment dependent on water sensor.

- With meters for Voltage, Current, Power, Frequency, excitation current.

- With indication lamps for main circuit breaker status, faults and alarms.

- With one button start, automatic excitation function, automatic storage function, automatic quasi synchronization function, automatic active power regulation function, automatic reactive power tracking function, automatic reducing power shutdown, automatic water level regulating operation function, automatically adjust the frequency and the power.